In perfect harmony

with nature

Forward-looking sustainability strategy

The company has long pursued a comprehensive, forward-looking sustainability strategy featuring environmentally compatible and biodegradable ingredients for cleaning products and innovative, recyclable packaging. The entire Werner & Mertz Group is a pioneer for a functioning circular economy far beyond its own industry.

Our Responsibility

for more Sustainability

The sustainability activities of Werner & Mertz increasingly have an effect beyond our own company: With the Frosch Initiative and targeted project partnerships we are leading the way with innovative, sustainable solutions. Detailed information can be found at our sustainability portal.

Green Care Professional:

Safe for humans and the environment

For more than 30 years the Green Care Professional brand has been synonymous with first-class cleaning performance and integrally sustainable cleaning under the sign of the circular economy.

A core element in our sustainability strategy involves obtaining demanding certifications.

We are a pioneer in the industry with the most Cradle to Cradle® certified products and are proud that we have proof of the recyclability of our formulas and our packaging.

Milestones

Founding of Tana-Chemie GmbH

Creation of Green Care Professional brand

EMAS-certified production site in Mainz. Followed by Hallein in 2005.

First EU Ecolabel certification

First Nordic Swan certification

Revision of development guidelines and publication of sustainability information for every product

First bottle with 30% share of recyclate

First Cradle-to-Cradle® Gold certification for a complete range of cleaning products

First bottle of 100% Post-Consumer Recyclate

Cradle to Cradle Products Innovator Award

Release of the Green Care Performance Calculator

German Environmental Award für Reinhard Schneider

German Packaging Award for the first fully recyclable monomaterial pouch

50 years of Werner & Mertz Professional

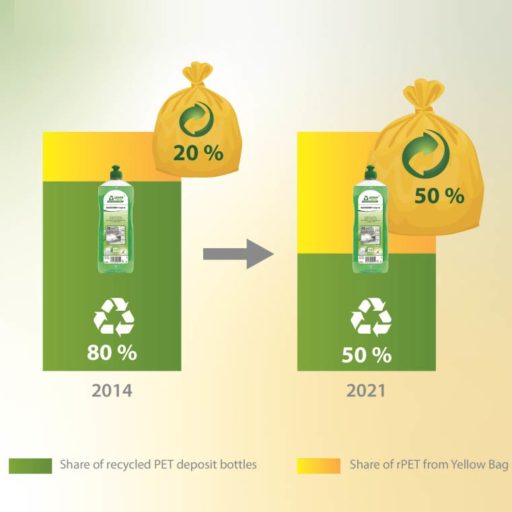

Increase in rPET to 50% from the Yellow Bag

Tana-Chemie GmbH wins EcoVadis Platinum Medal

True eco-effectiveness:

Doing the right things right

Sustainability is often mistakenly equated with efforts made to reduce pollutants. The process, however, has to begin much earlier so that the pollutants never get into circulation. A genuine circular economy goes even further and involves doing the right things right from the start. We live according to this credo along the entire value chain. The raw materials required for production are kept in biological and technical cycles and used again and again. It starts with the use of renewable energy in the production process and our efficient in-house water treatment and goes over integrally sustainable ingredients in formulas and beyond to packaging material made of recyclates.